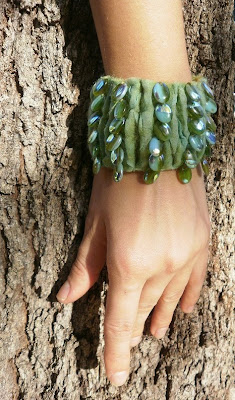

My collection will be heavily based on such textile technique as felting and particularly its advanced version - "

nuno felting". There is some introduction of that unique textile creation method.

"Felting" (which is thought to have originated in Asia) is one of the oldest textile processes and was used for hats, wall coverings, boots, blankets and the covering of yurts. Fibres, usually wool or other forms of animal fleece or hair, are manipulated to form a densely interlaced mass which can then be flattened, moulded or otherwise shaped. Felting is an efficient form of insulation.

"

Nuno" means fabric in Japanese. Nuno felting is a process which melds loose fibre, usually wool, into a sheer fabric such as silk gauze. This creates a lightweight felt that can totally cover the background fabric or be used as a single decorative design. The Nuno felting process is particularly suitable for fine garment making, since silk-backed felt ensures a stable felt that will not stretch out of shape like normal felt. Because it is lightweight and easy to manipulate it can also be dyed more readily than traditional felt. Other fabrics or open weaves can be used as the felting background, resulting in a wide range of textural effects and colours.

NUNO FELTING BASICS Step 1

Step 1 Lengths of hand dyed silk gauze were arranged on a long table which was covered with a cut piece of a swimming pool cover. Traditional see-through bubble wrap can be substituted. Next, thin bits of hand-dyed wool woven were arranged onto the gauze. Due to time constraints, we 'decorated' only the ends of our scarves.

Step 2 These layers were covered with a thin, almost sheer, nylon material. Having several hands helped to keep the roving from being disturbed as it was positioned. Next, cool water was worked into the layers.

Step 3 A bar of soap, fitted into a nylon sleeve was rubbed over the material.....along with more water until everything was fully saturated.

Step 4 The layers were carefully rolled up and tied tightly with strips of nylon (panty hose worked great for this task). Now the hard work began. Using the pressure of hand and arms, this 'log' was rolled back and forth on the table....for what seemed like hours....but was probably only 20 mins. This friction begins the process of matting the layers together so the fibers can work their way into the gauze.

Step 5 About every 50-100 rolls of the 'log', it was unrolled and checked for signs that it was beginning to felt. Until the fibers stick to the gauze (when they can no long be picked up between a finger and thumb), the rolling continues. Once it does, it's unrolled and more agitation on just the scarf is required. This again means the addition of soap and water and lots of picking up of the material and slapping it down onto the table. This where it can get messy.

The work is finished when the gauze has shrunk up and gotten distorted as the wool fibers have penetrated the material, becoming one.

image from